Waves Kickstarter Coming Soon

You’ve seen me blog here about technology, including Arduino processors, Pinoccio network computers, audio circuits, Processing.org animation, lighting systems, diffusion filters, light-weight mesh radio networks, and 3D printing. Very soon you will see how these come together into a new platforms called Waves.

My home temporarily turned into a television studio last week. Eaglevision Productions recorded me talking about Waves. The result will be an excellent Kickstarter video. Look for an announcement here AND sign-up today for the announcement list on the home page.

-Frank

Achieving Real Time Audio Streaming in Votsh Waves

Armed with the right tools we find meaning through storytelling, celebration, discovery, mourning, and myth making. These tools need to be real-time, including audio and light animation streams.

Our first experience using the LightWeight Mesh radio network technology in Pinoccio was good. We got the file transfer capability up and running in hours. But, the speed… only 600 bytes per second! Optimizations in the radio network connecting Waves now transfers a megabyte audio file in 1.6 minutes. That’s near real time streaming.

I created a slide deck on the techniques we used to improve Arduino Pinoccio LightWeight Mesh (LWM) radio transfer network transfer rates at

and a video explaining it at:

Please tweet about this and post to your favorite social networking sites. Thanks!

-Frank

A Day At The Maker Faire

An excellent new commercial is making the rounds on social media – LikeAGirl. It’s awesome to see people realizing that they are using the meanness of identification to put a person down. “You throw like a girl” and “You are cheap like a Jew”… both are aimed to rob a person of their humanity. A boy in the video is asked if what he just said insults his sister. He says no, then yes.

This period in time has failed so many people: Imagine being an immigrant in the US, imagine being poor (or marginally poor), imagine being a new college graduate in today’s job market. For these people the US has no answer today. Hopefully soon. So it’s just amazing to me that the country is able to make progress on self realization, self fulfillment, and self esteem.

Last weekend’s Pride festival and march was amazing. Imagine: people in love with one another can get married. Facebook added 50 gender neutral terms. And the popular culture is addressing this! (I’ll just listen to Same Love – Macklemore and Ryan Lewis – while I type this… “gay is synonymous with the lesser” burns in my ears.)

While identification is an issue, solving it needs more than just awareness. It needs something to do, something to manifest, something to look back on and say “Yes, I made that and it helped me feel good about myself!” That’s why I love the maker movement!

And let me tell you, there are a lot of young women in the maker movement. And they don’t throw like a girl, they print a 3D bat like a maker.

The Maker Faire is my place to charge-up my participation in the Maker movement. Makers make things. In the past I met fellow Oracle/Sun people making new microprocessors. And at the same time I met a Maker who developed a new way of making thread and yarn for knitting.

Makers span industries, communities, nations, races, and religions. The Maker Faire spawned the Maker Space movement (check out The Foundry as an example), 3D printing, social networks (like BoingBoing), the modern Internet of Things (IoT) and meet-ups. And the community of makers participate in the Northern California Renaissance Faire, Burning Man, and Dickens Faire.

Maker Faire 2014 at the San Mateo Fairgrounds in the California Bay Area hosted 15,000 makers. Here are some of the great things I found this year.

Assembling the giant head. It took 3 of us to put this together. I wish someone would remind me of the artist who created it!

Maker spawned the Arduino 8-bit hobby processor community. Pinoccio takes the Arduino into a distributed computing environment with built-in wireless networking.

Makers have wonderful skills. El Pulpeo Mechanico is Jerry Kunkel’s invention. It is about 50 feet tall and spews fire from 8 tenticles as it plays club music. To make him work requires integration from electrical systems, machining, project planning, creative artistry, and practical special effects.

DFRobot showed their laser keyboard kit. The kit projects a keyboard onto your desk and senses your fingers pressing the projected keys.

Maker Faire spawned the 3D printing community. Looking Glass uses the slicing technology developed for 3D printing to make glass boxes with volumetric images printed within. They have a successful KickStarter project too.

The PP3DP people showed the UP Mini 3D printer, now sold for only $600. I bought one and am very happy with the results.

Makable.com is a marketplace to buy and sell 3D printable objects.

Half the makers this year were kids. And there were many ways to get started.

Mesh Project puts electronic components into functional blocks. Kind of Lego on steroids.

Fuel3D makes a hand-held scanner to capture objects in the real world for use in the digital world. It scanned my face with incredible resolution.

Boxouse convverts shipping containers to tiny off-grid houses. They are starting a revolution in affordable housing.

Many supply chain and manufacturing organizations support makers:

- PCH International is a turnkey supply chain management company. You make the thing and they mass produce it.

- Meritronics does pc board assembly, BGA assembly, cable assemble, and global logistic support.

The makers from San Jose State University showed a full size replica of a new mass transit system, Spartain Superway.

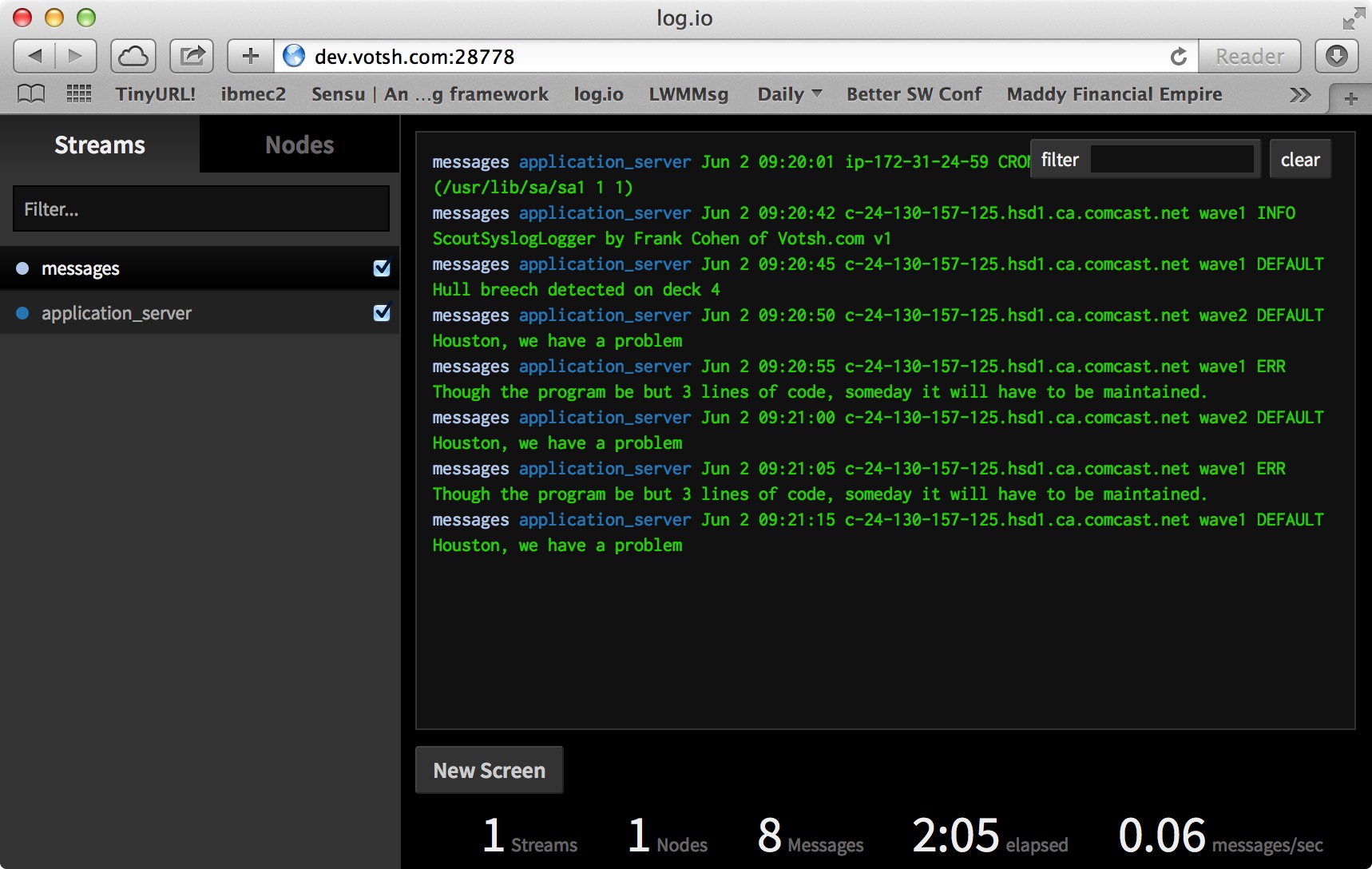

ScoutSyslogLogger, Web-based Log4j-style Logger

I published the ScoutSyslogLogger library. It is a Web-based Log4j-style logger for Arduino Pinoccio Scout Apps. I won’t be using the Serial Monitor anymore.

https://github.com/Votsh/waves/tree/master/ScoutSyslogLogger

The Votsh Waves project is perhaps a modern lava lamp, and maybe light therapy with a speaker. It uses Arduino Pinoccio technology in a distributed entertainment system running light, sound, and movement shows that span multiple networked boxes. While the Arduino IDE Serial Monitor is a fine tool to get started, in a distributed environment developers require sophisticated software development tools, including advanced and remote logging services.

Enjoy.

-Frank

Up Mini 3D Printer First Experience

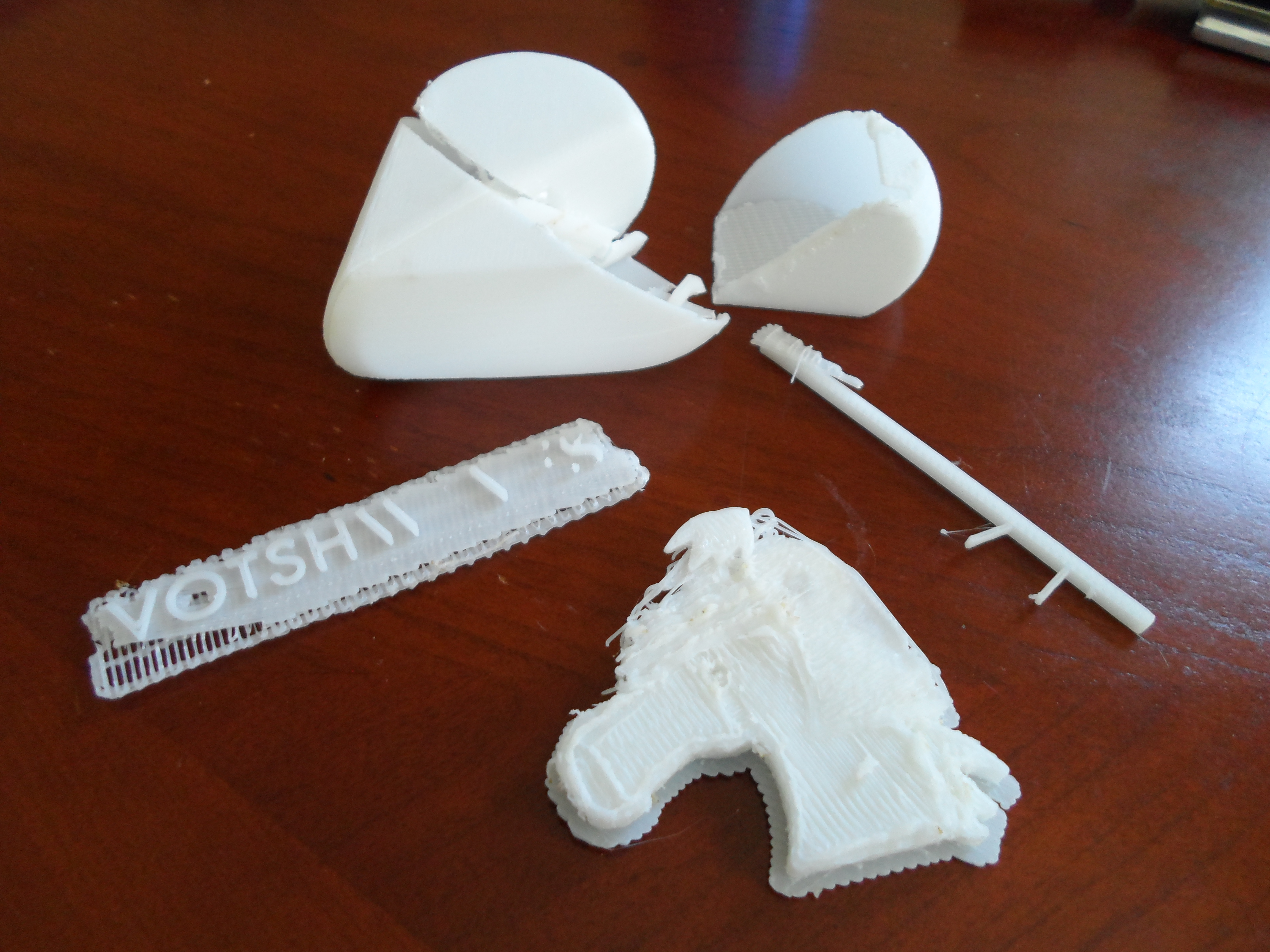

Votsh is building machines that animate light and sound to bring meaning to people’s lives. We are using 3D printing to prototype the Votsh Waves devices.

I have been using a Makerbot Replicator 2 at the San Jose Techshop. I found the Up! Mini 3D printer at the Maker Faire 2014 Bay Area last month. They announced a price drop to $599. Bought it through Amazon, now sold out. It arrived on Friday and I printed my first piece on Friday night. The unit comes fully assembled. I just needed to read the manual and get going. The results were not so pleasant, although I am now the coolest kid on the block, well at least for the moment.

- Up Mini comes with its own software. It runs on Windows and Mac. It takes STL files as input. It does the slicing and dicing. It sends the files over USB to the printer. The printer does not need to be connected once the transfer completes. The software lets you import multiple STL files and print them as one job. The software lets you manipulate the objects (rotate, scale, move). The software lets you calibrate the print platen height to the extruder head.

- I used the software to import an STL file, positioned it, calibrated the platen height, configured the job to print in “fine” mode, clicked print… and the software crashed. Not a good out-of-box experience.

- Support comes from a Web-based forum. It looks like pp3dp people participate in the forum. Don’t expect immediate answers – think a day instead of an hour. Also, the forum requires approval before you can post a question and that took me an extra day.

- I read on the forums that the Mac software has crashing problems. The work around was to save the project before printing. I did that and was able to print.

- The printer is basically blind and dumb. The on-off switch has a status LED that blinks depending on the operation. A speaker signals the start and end of a print job. Anything else is not available: no way to pause a print, no way to stop a print. The software allows you to add print pauses based on time during the print.

- The printer supports ABS and PLA. It comes with a spool of white ABS. I was not able to get anything to print correctly at first. The print head acted strangely – printing in the air, printing globs of plastic in random patches. I thought maybe I had a bad unit.

- The printer comes with 3 sheets of pc board like material with a grid of holes drilled through. These load into the print platen and the extruder head prints onto the pc board. The boards holes fill up with plastic and that forms the stickiness your objects need to grip to the platen. The system is kind of silly as trying to retrieve printed objects from the board doesn’t work for small objects. I found the small objects crumbled as I used the provided spatula to remove them from the board after printing. My solution was to buy a roll of blue printers tape and cover the pc board. That even works for ABS when the pc board is heated by the printer.

- Temperature controls are limited by the software. It chooses for you PLA at 220 C and ABS at 255 C. For ABS it turns-on the bed’s heater. This is supposedly to encourage you to only use plastic purchased from pp3dp. There are hacks to get around this and set your own temperature, for example http://thevariableconstant.blogspot.com/2014/02/peeling-up-up-mini-temperature-hack.html

- The software ignores the “No Raft” option for one of my print jobs. It doesn’t print the full raft, instead it prints a mini single-strand of waves around the base of my object. Still have not found a way to have it only print the object.

- I printed from a spool of MakerBot PLA TrueBlue I had purchased and had a really bad experience. The extruder head jammed on feeding the PLA. It was so bad that I had to disassemble the head, remove the PLA, and assemble it again. I believe it is the fault of the PLA and not the printer as I have had problems with this spool on a MakerBot Replicator 2 before.

- The printer head is held onto the printer by 3 magnets. I have seen the head hit the object is was printing so hard that the head temporarily came apart from 2 of the 3 magnets. The printer continued to move the head and it reattached. Maybe that’s the design, but it was shocking to see this happen.

So far I have printed only 1 thing successfully, http://www.thingiverse.com/thing:44579, of the 8 I tried. I feel like I’m at the middle of a long Up Mini learning curve.

-Frank Cohen